In the first week of our class preparing us for the Green Belt Six Sigma exam, our instructor Bob Mehta introduced the 5 basic steps of the Six Sigma method of quality improvement that are summed up in the acronym DMAIC: Define, Measure, Analyze, Improve, Control. These steps are summed up in the table below the diagram.

|

Six Sigma Step |

Definition |

|

| 1. | Define | Define customer and organizational requirements. Select the “Y” responses to be improved. |

| 2. | Measure | Measure what is critical to quality, map the process, establish measurement system and determine what is “out of specification” or unacceptable. Measure the “Y” response variable. |

| 3. | Analyze | Now develop a baseline (the process capability), set objectives, identify the “X” independent variables that are the root causes of defects or “out of specification” measurements of the “Y” response variables. |

| 4. | Improve | Improve the process by reducing variability in the process or eliminating the cause of the defects or out of spec measurements. |

| 5. | Control | Establish a system to monitor and control the process to sustain the improvements in the long term. |

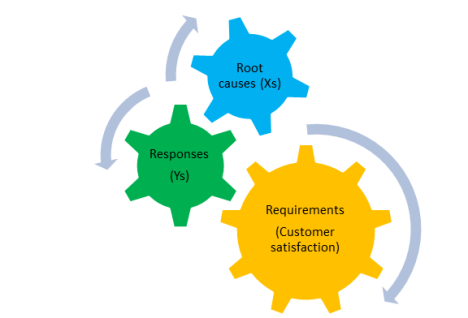

As you can see, the DMAIC approach takes the requirements of the deliverables to be improved, whether they are internal (organizational) or external (customer), maps the processes that create these desired responses, then analyzes them to identify the root causes or any defects. These root causes are improved, which then improves the responses, and thus increases the satisfaction of the requirements. By showing how the system of causes, responses, and requirements are linked, as in the schematic diagram below, you improve the satisfaction of the requirements (increasing quality) by eliminating the root causes of defects.

This, in a very summary form, is what the DMAIC steps to Six Sigma are all about.

Filed under: Uncategorized |

Leave a comment