1. Value

The concept of value is an important one in lean production. Value is the customer perception of the usefulness & necessity of a given product or service at a target cost based on competition and elimination of waste by lean methods.

2. Value Chain

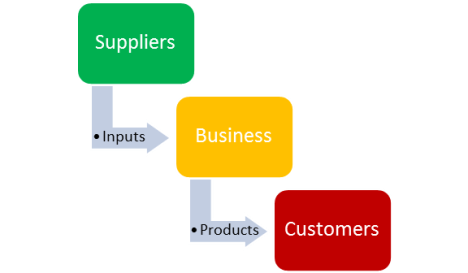

The value chain connects both business-to-business operations and business-to-customer relations in the following way. In the value chain, the production flows from inputs that suppliers send to businesses, which then process them into products, which are bought by customers.

Fig. 1 The Value Chain–Production Flows

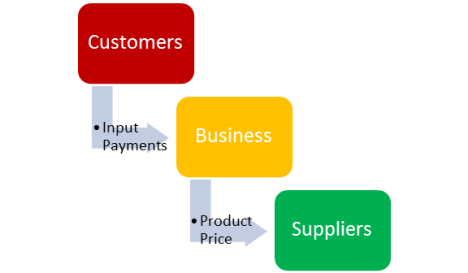

This engine of growth is fueled by the monetary flows going in the other direction, from the product price paid by the customers to the business, and the input payments paid by the business to the suppliers.

Fig. 2 The Value Chain—Monetary Flows

3. Value Stream

The value stream is a series of organizational activities that are performed in a specified sequence. Examples include the flow of raw materials to be processed, the transformation of those raw materials in the process, or the flow of information in a computing process.

The idea is to map these activities and identify and eliminate the waste or muda in Japanese in the value stream in the following way.

First identify all activities involved in the process. Then analyze them according to whether they add value or not. If they do not value, ask if they are required by the process. If they do not value nor are they are required by the process, then they should be eliminated.

| Activity Type | Eliminate? | |

| 1. | Adds value as perceived by the customer | NO |

| 2. | Adds no value, but required by the process | NO |

| 3. | Adds no value | YES |

The next post goes into some more details about the value stream map and analysis.

Filed under: Uncategorized |

Leave a comment