1. Value Stream–definition

The value stream is a series of organizational activities that are performed in a specified sequence. Examples include the flow of raw materials to be processed, the transformation of those raw materials in the process, or the flow of information in a computing process.

The idea is to map these activities and identify and eliminate the waste or muda in Japanese in the value stream in the following way.

First identify all activities involved in the process. Then analyze them according to whether they add value or not. If they do not value, ask if they are required by the process. If they do not value nor are they are required by the process, then they should be eliminated.

| Activity Type | Eliminate? | |

| 1. | Adds value as perceived by the customer | NO |

| 2. | Adds no value, but required by the process | NO |

| 3. | Adds no value | YES |

2. Value Stream Mapping

There is a tool for for eliminating waste or muda in the value stream, and that is value stream mapping.

| Mapping Step | Description | Symbol used | |

| 1. | Map suppliers and customers

|

Symbolize suppliers that feed production inputs, and customers that receive production outputs.

|

|

| 2. | Map process steps | Symbolize every process on the production path of the material or information. (Lower part of box is for cycle time, batch numbers, etc.) |  |

| 3. | Map storage/ inventory steps

|

Symbolize steps between processes where material/information is stored.

|

|

| 4. | Analyze process steps

|

Analyze process steps: either it is value-added (VA), or non-value-added (NVA).

|

NVA or VA |

| 5. | Draw value-added timeline

|

At bottom of map, put timeline underneath processes showing time for both VA and NVA activities.

|

|

| 6. | Future state map

|

Redo the present state map eliminating those NVA process steps that are not required by the process.

|

(all of the above) |

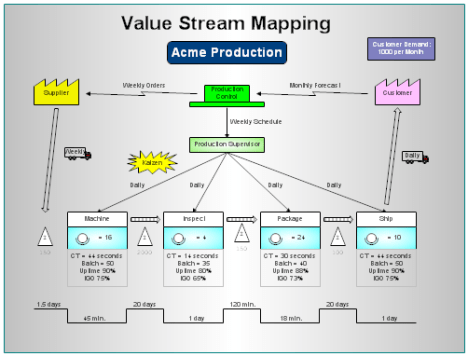

3. Value Stream Mapping Example

(The above diagram was taken from www.rff.com, RFF Electronics, a company that produces professional charting software for flowcharts, organizational charts, etc.)

Step 1. Supplier/Customer

The supplier is denoted by the yellow symbol, and this is brought weekly to the Acme Production company (denoted by the truck symbol) where it is an input to the process. When the widgets (or whatever it is Acme Production is producing) are finished, they are shipped daily to the customer, who is denoted by the pink symbol.

Step 2. Map Process Steps

The company does a monthly forecast of the customer demand, which then causes production control to order the production supervisor to make the parts on a weekly basis. The input is a) machined, b) inspected, c) packaged, and d) shipped as an output. Each of these four production steps is indicated by the rectangular box with the label of the process on top and the specific information about the process (CT = cycle time, batch size, uptime, IGO).

Step 3. Storage/Inventory Steps

Storage and/or inventory steps before processing or between processes are those denoted with the triangle above.

Step 4. Analyze Process Steps

Obviously the process steps are value-added, and the inventory or storage steps identified in Step 3 above are non-value-added.

Step 5. Draw VA/NVA timeline

In the above example, please note that the timeline has the value-added activities on the bottom lines and the non-value-added activities on the top lines, the opposite direction as indicated in the chart. It is important that it is clear to the organization which is which.

Step 6. Future state map

This example is a CURRENT state map; if the inventory or storage steps were reduced as much as possible, then a redrawing of the production path with the reduced NVA steps would be the FUTURE state map.

4. Conclusion

There are many other symbols used in the Value Stream Map, but the ones listed above are the basic ones that you must understand to be able to comprehend such a map. Agan, the purpose of such a map is to minimize non-value added activities. There are additional lean techniques, which will be discussed in the next post.

Filed under: Uncategorized |

Leave a comment