I went to the polling place this morning here in Anaheim, CA, hosted by a local elementary school in order to cast my vote in the US national, state, and local elections. As I left after having cast my vote, parents were dropping their children off to the school. This made me think about how the decision to be made in the next 24 hours about the US Presidency will affect not just my life, but eventually the lives of those children as well.

Earlier this year, I had written a blog post about the future trends identified by the World Economic Forum or WEF, and I thought of posting something today to recap these trends as a way of reminding people at what is at stake. It occurred to me that whoever wins the US Presidency will have to deal with these global trends, and any hope for the future is tied up with how well they handle them over the next 4 years.

1. Introduction

The World Economic Forum held in Davos, Switzerland puts out a Global Risk Report every year which outlines global risks in 5 categories, which are given below in a color-coded list.

Fig. 1 Global Risk Categories

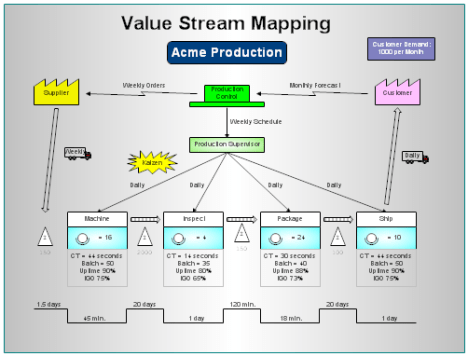

2. Most Likely Global Risk Factors

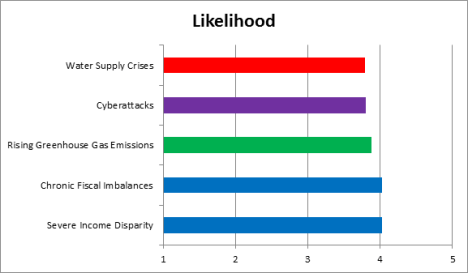

The seventh edition of the Global Risk Report ranks the 50 global risk factors according to their a) likehihood and b) impact on a scale from 1 to 5, with 1 meaning “least likely or severe” and 5 meaning “most likely or severe”. Below are the global risk factors thought to be the most likely to affect the global community in the near future.

Fig. 2 Most Likely Global Risk Factors

a. Severe Income Disparity

This creates political pressure on governments to step in and correct this perceived imbalance, and can be a factor pushing political extremism. In the United States, it has led to the Occupy Wall Street movement on the left and the Tea Party on the right, both of which were created in protest of the bailouts of the financial sector by the US Government in 2008. If another bailout is required due to the failure of big banks in wake of a possible breakup of the Eurozone, there will be a lot of populist pressure in the US against another set of bailouts.

b. Chronic Fiscal Imbalances

There is pressure on the US government to reduce debt, but austerity measures which reduce government spending also have the side effect of reducing economic demand, as has been found by the governments of Europe. The US has avoided the extreme economic austerity measures tried in Europe, and has as a result avoided the economic contractions experienced there.

The negotiations regarding the so-called “fiscal cliff” in January 2013 may result in polities which increase these chronic fiscal imbalances.

c. Rising Greenhouse Gas Emissions

Hurricane Sandy shows that the economic cost of rising greenhouse gas emissions will continue to grow. There is an incentive for large companies involved in fossil fuel extraction to downplay the risks because they fear that regulations to curb greenhouse gas emissions may impede their ability to extract these resources and thus to make profits. However, insurance companies may become increasingly vocal about how paying for damage due to weather-related disasters effected by rising greenhouse gas emissions will affect their ability to make profits. Two areas the President can most effect this risk are in formulating energy policy and in infrastructure spending to repair and to prevent damage due to extreme weather events. However, the ability for the US government to engage in this infrastructure spending is tied up with the negotiations mentioned above in paragraph b).

d. Cyberattacks

Comparing the global risks identified in the seventh edition of the Global Risk Report http://www.weforum.org/reports/global-risks-2012-seventh-edition to those identified in previous reports, this is the first time in over five years that a technological risk (Cyberattacks) has been identified . These cyberattacks take the form of attacks by a) government vs. government, b) government vs. individuals or corporations and vice versa and c) corporations vs. corporations. The US President will have to make sure that the Department of Homeland Security pays sufficient attention to the threat of cyberattacks from foreign governments. He will want to strengthen the hand of the US Government to have access to privately held information from both corporations and individuals for security reasons without depriving those same individuals of their rights guaranteed by the very Constitution the US Government is allegedly supposed to uphold. That is a very fine needle to thread. The US government should try to make sure it does not get used in the attacks of one set of corporations by another, as are threatened by laws that would essentially have the government be the guarantor of private copyrights of entertainment corporations or the monopolistic control of corporations which distribute entertainment, at the expense of other corporations which survive on a model of the free flow of information (so called “net neutrality laws”).

e. Water Supply Crises

As a side effect of the global risk in paragraph c, drought in many areas of the US is driving up food commodity prices, which in turn distorts the market for alternative energy subsidies that encourage the diversion of food crops to produce biofuels. Attention will have to be paid to regional water agreements such as those on the West Coast that they do not unravel in the face of continued droughts.

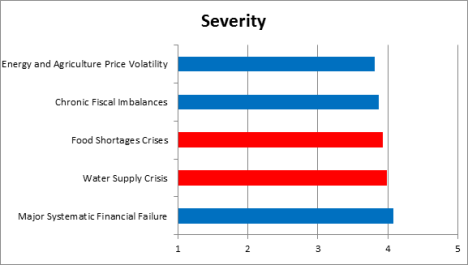

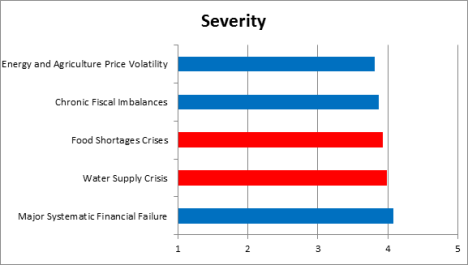

3. Most Severe Global Risk Factors

Fig. 3 Most Severe Global Risk Factors

a. Major Systematic Financial Failure

The biggest concern here is the Eurozone when it unravels. Will it be a controlled implosion or an explosion of panic? Even if it is a controlled event, the US financial markets are so invested in the Eurozone that one or more banks may not survive the collapse. If so, will the US Government bail out those banks one more time? Whichever President does will save the financial sector at a great political cost in the next election.

b. Water Supply Crisis and c. Food Shortages Crisis

This was dealt with above in the section on “likely” risks. Droughts will cause a food shortage crisis, and increase the need for those on food stamps and other financial aid from the government to survive. However, there is simultaneous pressure on the President to cut domestic programs including food stamp programs as part of the negotiations to reduce the Federal budget.

d. Chronic Fiscal Imbalances

This is also on the hit parade of most likely global risks (along with water supply crises), so the President has to take a stand on reducing the deficit in the medium to long term without introducing austerity measures that will increase the deficit in the short term and increase political instability as well.

e. Energy and Agriculture Price Volatility

Remember that the Arab Spring, although taking the form of political revolution, had its origins in the economic depression faced by these countries that was exacerbated by rising fuel and food costs. Droughts will increase agriculture price volatility, and any move which politically destabilizes the Middle East will increase energy price volatility.

In the case of a potential attack by Israel against Iran’s nuclear facilities to prevent them from producing nuclear weapons, the US has so far restrained such an attack because the decrease in the perceived risk to Israel might be offset by the increased geopolitical risk in the Middle East that such an attack might set off, plus the risk to energy price volatility that such an attack would definitely set off. Will such balancing of risks continue after the US presidential election is over?

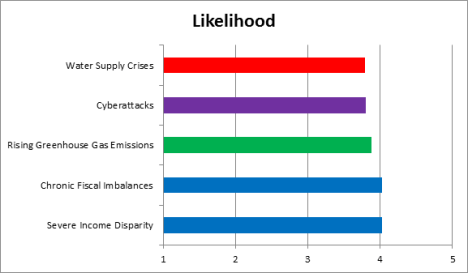

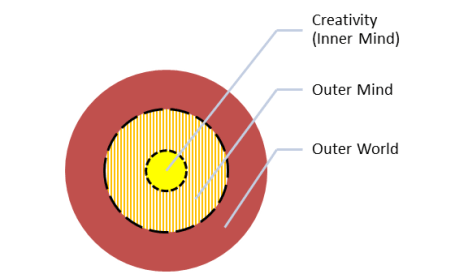

4. Interaction of Global Risk Categories

The diagram shows how these five global risk categories link up to each other. The technological risk of cyberattacks is part of a more generalized “critical systems failure” risk, and the societal risks of water and food shortages, are subsumed under “unsustainable population growth.”

Fig. 4. Global Risk Centers and How they Interact

You will notice that all of these categories of risk connect to the geopolitical risk of “global governance failure.” The task of the next President will be to make wise decisions that reduce this geopolitical risk of global governance failure by being part of the solution, and not exacerbating the problem. That is what is at stake in today’s election.

Filed under: Uncategorized | Leave a comment »